The Philosophy: Beyond the Black Box

Because in Aerospace, "Trust Me" Isn't a Validation Strategy.

Standard AI is often a "Black Box"—you feed it data, and it spits out an answer with no explanation. In high-stakes engineering, that is a liability.

We believe in Assistive Intelligence. SCOTi PLM is built on transparency and human-in-the-loop validation. It acts as your Master Builder, not a replacement. Every requirement generated, every risk flagged, and every decision proposed is traceable, ethical, and secure. We enable your team to think slow and logically before they act fast, ensuring that the machine’s scale never outpaces human critical thinking.

The SCOTi® Solution: From Data to Wisdom

SCOTi® doesn't replace your existing systems; it sits on top of them as a System of Intelligence.

It Remembers: SCOTi® carries the "Wisdom of 1,000 Projects," applying 50,000+ domain-specific questions to your data to find errors before they reach the shop floor.

It Connects: While your ERP sees a "part number," SCOTi® sees the entire history of that part, its sub-assemblies, and its regulatory requirements.

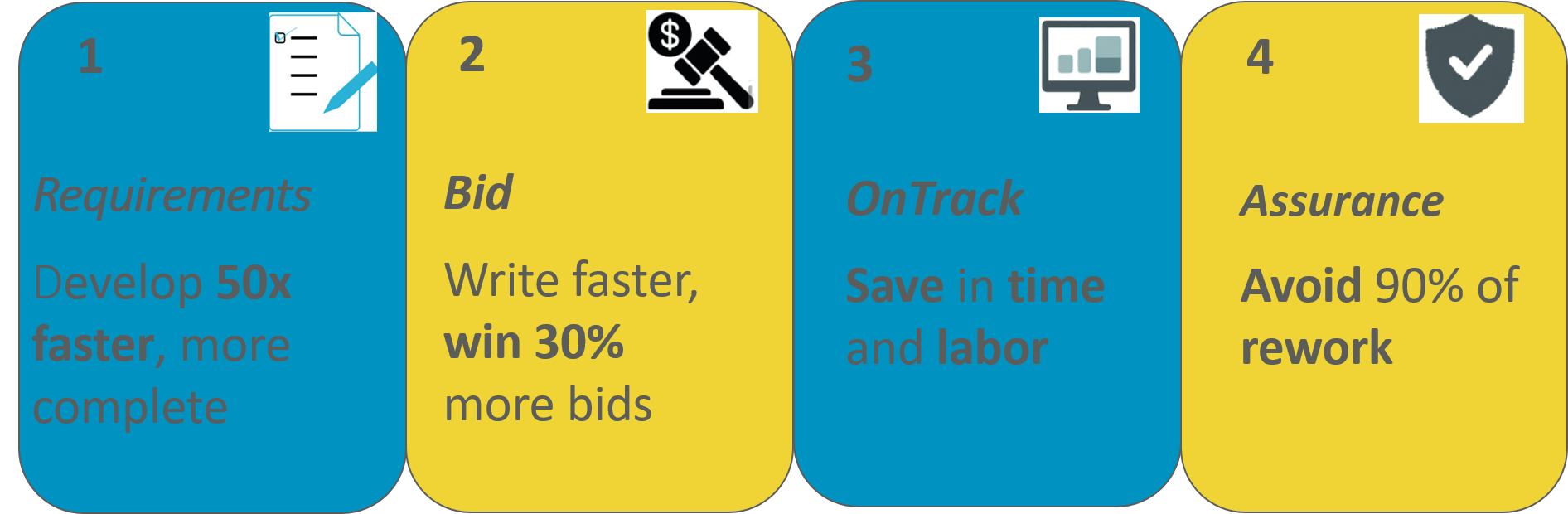

It Fixes: By bridging the gap between what you know and what you do, SCOTi® helps you plan 65x faster and prevent 90% of the rework that fuels the backlog.

INTRODUCING SCOTi PLM

Meet Your Master Builder: An Autopilot for Product Lifecycle Management

Imagine a digital partner that has securely analyzed the patterns of every past project within your organization. Someone who remembers every lesson learned, every failed test, and every requirement that caused rework.

That is SCOTi. SCOTi® PLM is a private, secure, on prem Agentic AI ecosystem that breaks complex projects into "proven modular bricks”. It acts as a force multiplier for your experts, running over 50,000 diagnostic questions to surface crises while they are still cheap to fix.

The Aerospace Backlog Isn't a Supply Problem. It’s a Complexity Problem

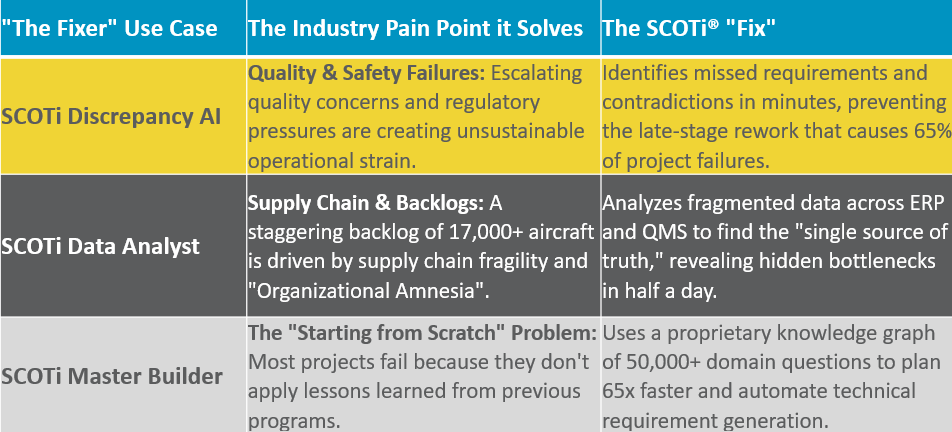

From "Theory" to "The Fixer" - SCOTi®: The AI "Fixer" for the Industry’s Most Expensive Mistakes.

The aerospace industry is currently paralyzed by a "Complexity Gap" where demand is high, but delivery is failing due to fragmented data and structural inefficiency.

-

Don't wait for a failure during certification. SCOTi® cross-references your design against 50,000+ global standards and historical safety data to find the "unknown unknowns" before they become grounding events, stopping the rework!

-

Your ERP is full of data, but your production line is still stalled. SCOTi® acts as a digital detective to synthesize fragmented supply chain data, identifying the exact business rules needed to get parts moving again.

-

Engineering a 787 shouldn't take 3 years longer than planned. SCOTi® provides the "Assistive Intelligence" to write requirements in minutes and plan with the wisdom of 1,000 previous projects.

"Caught 100% of missed requirements in 1 hour that manual human review missed for weeks."

"Reduced data synthesis from 6 months to 4 hours."

"Plan 65x faster and win 30% more contracts by eliminating 'Starting from Scratch'."

Your Data, Your Walls

The world’s most sensitive organizations—in defense, aerospace, and healthcare—cannot compromise on data sovereignty.

SCOTi® is totally private. It lives securely within your organization’s walls (on-premises or private cloud). Your IP never leaves your control. With built-in compliance for NIST, ITAR, and HIPAA, we provide the reward of cutting-edge AI with zero of the risk.

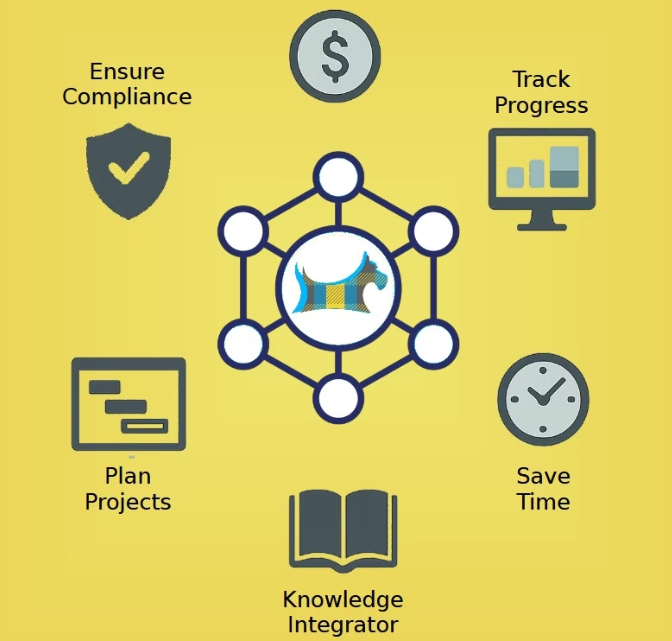

The Five Superpowers of SCOTi PLM

The Guardian (Continuous Compliance)

Automated traceability from System Requirements to LLRs. Gaps are flagged instantly. You are always audit-ready for FAA/EASA certification.

The Diagnostic Engine (50,000+ Scrutiny Points)

While human teams cannot manually ask 1,000 questions per requirement easily, SCOTi can. It flags ambiguities and missing standards in a single morning.

The Decomposer (LEGO-Brick Architecture) SCOTi maps new projects to functions your organization has successfully implemented before, making the unpredictable predictable.

The Scenario Lab (Right-to-Left Planning)

Model high-level tradeoffs like SWaP, Power, and Cost in real-time. Work backward from the end goal to build a plan before committing significant capital..

The Knowledge Integrator (Enterprise Memory)

Captures and ingests your organization's complete history-past architectures, test results, and supplier performance-so your tribal knowledge never walks out the door again.

The Tribal Knowledge Hoover

The Problem: Your organization’s greatest asset—experience—is often trapped in data silos, old PDFs, or the "unwritten rules" of senior engineers about to retire.

The Solution: SCOTi hoovers this fragmented data, sucking up structured and unstructured information to capture all the "Tribal Knowledge" that makes your company unique. It converts messy history into executable wisdom.

The Engineering Master Builder for Complex Aerospace Projects

Knowledge Trees

The Logic: SCOTi doesn't just store data; it organizes it into a Knowledge Tree. This integrates past project requirements, test cases, and lessons learned into a structured hierarchy of experience.

The Benefit: This allows your team to stop searching for information and start using it. By visualizing the "DNA" of your past successes, SCOTi helps you ask the right questions to ensure superior outcomes for future projects.

Guided by Your Experts: The Human-in-the-Loop

SCOTi does not replace the engineer; it empowers them. Because deep technical domains require human judgment, SCOTi acts as a high-speed filter. It ranks and prioritizes the most critical risks, allowing your reviewers to focus their time on what truly matters rather than searching through thousands of pages of documentation.

Snap-to-Fit Precision

Modularity was the secret to the Empire State Building’s rapid success, and it is the secret to SCOTi. We treat complex project requirements like building blocks.

Using our Modular Requirements Generation, SCOTi PLM snaps complex projects together piece by piece. It starts by analyzing your project's goals against its “Knowledge Tree” to propose a baseline of System-Level Requirements (SLRs). From there, it automatically flows them down into high-level and low-level tasks, ensuring that every "Lego brick" in your engineering process is perfectly aligned, logically consistent, and 100% traceable.

Business Case Studies: Measured Outcomes

The Speed of Intelligence

Metric: >95% Reduction in Drafting Time.

Detail: Reduced initial requirements drafting for a major aerospace manufacturer from 6 months to just 3 days.

Don’t just manage projects—redefine what’s possible. With SCOTi, you’re not just keeping up with the competition—you’re leading the way.

De-Risking the Future

Metric: 90% Slash in Rework Risks.

Detail: SCOTi identified critical requirement gaps and ambiguities that had been missed by senior PMs, preventing catastrophic post-hoc errors.

-

The Impact Metric: 80% Reduction in Data Preparation Time.

The Challenge: A major aerospace manufacturer was "data-rich but insight-poor," with 40 years of fragmented, undocumented legacy data. Cleaning this data manually to enable AI-readiness was deemed prohibitively expensive.

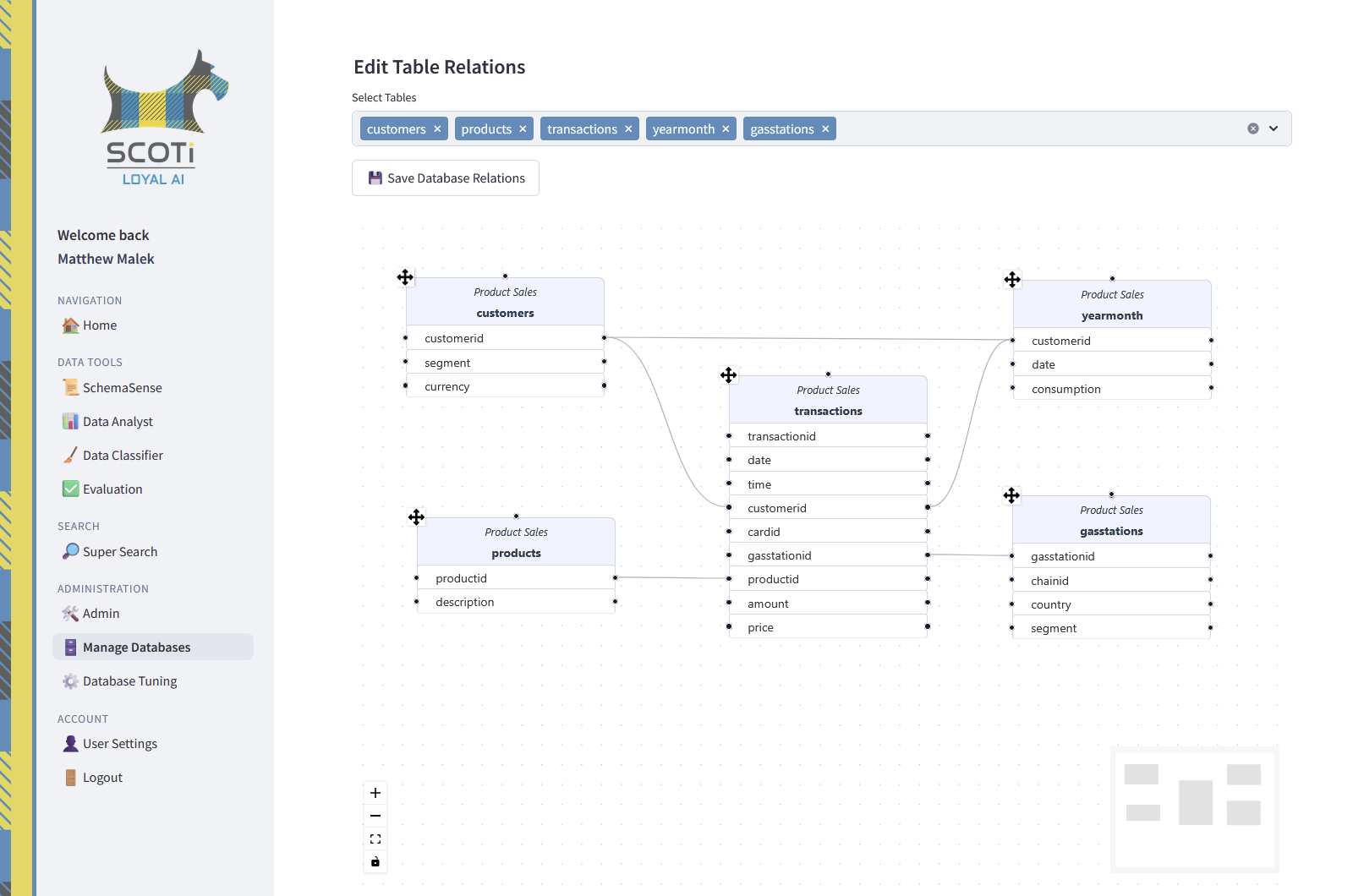

The Solution: Deployed SchemaSense on the SCOTi platform to automate data profiling and documentation. The AI automatically flagged anomalies and assigned "Confidence Scores" to data descriptions, allowing humans to focus only on high-risk areas.

The Result: A fully AI-ready data estate. Analysts shifted from spending 80% of their time cleaning data to 100% of their time generating insights.

-

The Impact Metric: Drafting Time Slashed from 6 Months to 3 Days.

The Challenge: Engineering managers faced "underbidding" risks and "engineer bottlenecks" where bid support lagged due to limited bandwidth.

The Solution: SCOTi® acted as a digital autopilot, ingesting historical project data and tribal knowledge to generate a complete, compliant requirement set 30% faster.

The Result:50x faster requirements generation. The system identified flawed requirements missed by project managers, preventing costly post-contract rework.Description text goes here

-

The Impact Metric:10% Reduction in Multi-Million Dollar Build Costs.

The Challenge: Traditional warehouse design relies on "average" order sizes, leading to operational chaos and sub-optimal layouts.

The Solution: In partnership with sSy.ai, SCOTi® simulated "What-If" scenarios based on real order profiles, optimizing automation levels and zone pairing.

The Result: Enabled design firms to handle 20–30% more bids. One layout optimization reduced picker walking by 30% and prevented revenue-killing design errors.scription text goes here

Engineering Efficiency

Metric: 80% Automation of Manual Tasks.

Detail: By handling the tedious, error-prone work of requirement management and traceability matrices, SCOTi saved an estimated 1 man-year of effort per major project.

Proven Outcomes. Engineered for Success.

We don’t just build AI; we solve the most stubborn bottlenecks in complex engineering. From taming decades of legacy data to accelerating multi-billion dollar aerospace bids, see how SCOTi and the smartR team deliver measurable ROI across the globe.

-

The Impact Metric: 1,000x Faster than Manual Analysis.

The Challenge: Organizations collect vast amounts of unstructured data (incident reports, surveys, feedback) that are too labor-intensive to analyze manually.

The Solution: SCOTi®’s Free-Text Classification allows users to ask natural language questions (e.g., "How many complaints mention delivery delays?") to instantly categorize thousands of records.

The Result: A million-record database can now be processed for less than $1. One clinic identified a 30% rise in specific health symptoms through automated trend reports.tem description

-

The Impact Metric: 90% Reduction in Sensor Positioning Errors.

The Challenge: Low-cost IMU sensors (found in smartphones and wearables) suffer from "drift" and noise, making them unreliable for mission-critical tracking in healthcare or robotics.

The Solution: A neural-network-based algorithm that dynamically corrects sensor bias and orientation in real-time.

The Result: Unlocked high-precision 3D reconstruction and motion tracking on low-power edge devices, enabling superior fall detection and industrial robotic navigation.